Different Hardwood Cuts – Rift, Quartered and Plain-Sawn Hardwood

The lumber that is used to create your hardwood flooring is partially defined by how it’s been cut at the saw-mill. When you think of a cut log, you may imagine it’s growth rings. Now you may be wondering why it’s even important to know what way your hardwood flooring material was cut from the tree; but believe it or not, the cut plays a big role in your floorings’ overall mechanical properties and even what the graining looks like! The most accurate way to tell the cut of your lumber or flooring is by examining its end-grain.

Typically, these are the three different ways that lumber is cut from logs.

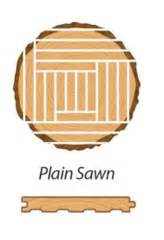

Plain or Flat-Sawn Lumber –

“Plain-Sawn,” also referred to as “Flat-Sawn” is the most common and least expensive cut of the three. Plain-sawn lumber is created by cutting the log in long straight lines from the front to the back, perpendicular to the trees growth rings. This cut utilizes the most amount of the actual tree with minimal waste. Many of the beautiful hardwood slabs you may have seen as tables or other furniture, are Plain-Sawn lumber.

Structural properties – More prone to being effected by moisture. (more movement, higher possibility of cupping or crowning when moisture or excessive heat and/or humidity is introduced)

Appearance – (depending on the wood species) In general, most common domestic hardwoods that have been Plain-sawn are known to have a “Cathedral” look to them because they’ve been cut through the trees’ growth rings. This means that, for example, if you purchase Plain-sawn white Oak flooring, the majority of the flooring will look like the image below

Plain Sawn Red Oak Hardwood

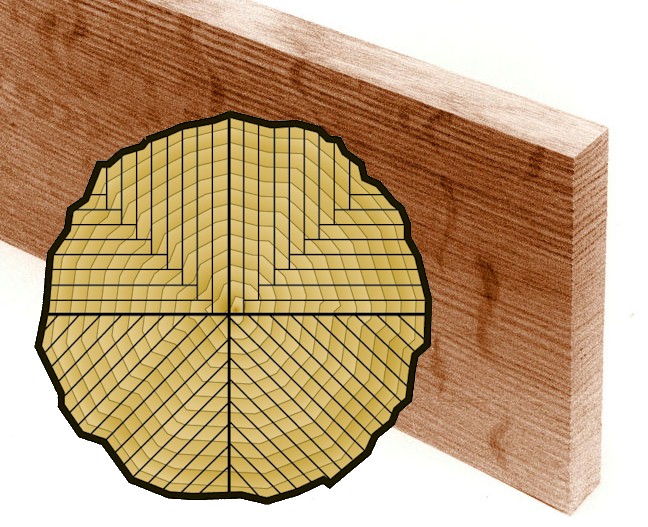

Quarter-Sawn Lumber –

When a log is Quarter-sawn, it’s cut just like it sounds; in quarters at first, then each quarter of the log is cut from the inner heart-wood toward the outer sap-wood. It’s much easier to explain with images than words, so we’ve included some diagrams below. Quarter-sawn lumber is more expensive than Plain-Sawn and also doesn’t utilize the entire tree. The majority of Quarter-sawn lumber will have mostly vertical end-grains, giving this cut lumber, or your flooring, a higher amount of stability compared to Plain-sawn hardwood. The more vertical the end-grain, the more structurally stable the lumber is.

Structural properties – Quarter-sawn lumber is known to have a minimal reaction to moisture and climate change, this cut naturally resists cupping and crowning and also has less expansion and shrinkage (overall movement). That doesn’t mean that you can get away with your home flooding, but it IS less likely to cup, crown, warp and twist over time.

Appearance – Quarter-sawn lumber has beautiful aesthetic qualities that is often sought after for fine furniture as well as musical instruments. Quarter-sawn Oak, as well as domestic Cherry and Maple show higher luster and also a dramatic amount of surface flecking (also known as “Ribbons”) which makes for a gorgeous flooring choice.

Quarter-Sawn Lumber

Quarter-Sawn Oak Hardwood

Rift-Sawn Lumber –

You can think of Rift-sawn lumber or flooring as being cut like a pie is. Only a lot of the wood in between these cuts unfortunately go to waste, making this choice of cut the most expensive of the three. Rift-sawn lumber has only vertical end-grains, making it the most structurally stable cut, as well as the most wasteful. Because there is so much wasted material when cutting lumber this way, you can more commonly find Rift-sawn wood accompanied by Quarter-sawn; Commonly known as “Rift and Quartered Hardwood Lumber or Flooring.”

Structural properties – The most dimensionally stable cut of hardwood lumber. More stable that both Plain-Sawn and Quarter-sawn Lumber, also naturally resisting cupping and crowning effects from moisture/humidity.

Appearance – Like quarter sawn wood, Rift-sawn lumber and flooring have very straight grain lines in most common domestic hardwood species, but with Rift-sawn wood, there is not flecking or added visual luster in the pieces.

Rift-Sawn Cut Diagram

Rift and Quarter-Sawn Red Oak Hardwood Flooring

Why it’s important to know how your hardwood flooring is cut –

The old adage is “The wider the hardwood plank, the more moisture it can and will hold onto and be effected by.” Knowing what cut your hardwood flooring is, isn’t just for aesthetic reasons, it’s mainly structural! For example, if you’re thinking about installing a wide plank hardwood floor in your home, (that means pretty much anything that’s 5 inches wide or wider) you may want to consider opting for “Rift and Quarter-sawn” flooring. The wider the flooring plank is, the more susceptible to movement it will be, including unwanted cupping and crowning from humidity levels in your home. When a wide-plank floor is cut “Rift and Quarter-sawn,” it elevates a LOT of that movement and risk of damage from moisture. Granted, it will cost more than plain-sawn, but remembering that a stunning hardwood floor is an investment for your home, immediately adding value, pushing for the more stable material is a really smart choice that will prove to be well-worth it in the long run!

5 Comments

Pingback:

Pingback:

Pingback:

Pingback:

Pingback: